Labels for Safety, Visual and Facility ID Desktop Printers

Arc Flash Labeling Requirements

How to Properly Label Your Equipment to Meet NFPA 70E

Overview

The National Fire Protection Association (NFPA) details how to comply with the Occupational Safety and Health Administration's (OSHA) regulation, 29 CFR 1910.333(a), through the NFPA 70E standard.

According to the NFPA 70E standard, there are six primary responsibilities that facilities must meet. These responsibilities include:

- Training for employees

- Written safety program in place that is actionable

- Personal Protective Equipment (PPE) available for employees

Arc flash labeling is the responsibility of the employer, not the manufacturer or installer of the equipment. Labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized, creating the potential for an arc flash incident to occur.

What Equipment Requires An Arc Flash Label?

In order to comply with the label requirement of NFPA 70E, your team should understand what electrical equipment needs to be properly labeled for arc flash.

Here are a few examples of locations an arc flash label should go.

Switchboards

Ideal for un-terminated wires or cables needing superior abrasion and chemical resistance.

Panel Boards

Ideal for general marking of terminated or unterminated cables and wires that may be curved or become curved.

Industrial Control Panels

Ideal for terminated cables or wires that may need additional abrasion or chemical resistance.

Motor Control Centers

Ideal for getting larger amounts of data on small diameter wire and cables such as fiber optic cables.

Production Line

Ideal for multi-conductor cables or bundled wires/cables.

Disconnect Switches

Ideal for multi-conductor cables or bundled wires/cables.

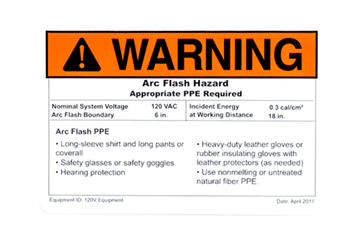

Seven Elements of an Arc Flash Label

Now that you’re familiar with the equipment that needs labeling, here are the elements you will need to include in your arc flash label.

Danger or Warning header.

A common guideline is to use the "Danger" header when the voltage is over 600 or when the incident energy is over 40 cal/cm2. If it is less than this threshold, an orange "Warning" header is typically used.

“Incident Energy at” is the corresponding working distance.

The Institute of Electrical and Electronics Engineers (IEEE) defines this as, “the dimension between the possible arc point and the head and body of the worker positioned in place to perform the assigned task.”

“Min. Arc Rating” is the incident energy.

A measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault.

Arc Flash Boundary.

This is the shortest distance at which a person working at the time of an arc-flash may receive permanent injury (the onset of a second degree burn or worse) if not properly protected by flame-resistant (FR) clothing.

Personal Protective Equipment (PPE).

Each hazard risk category requires a different level of protection. Categories range from 1 to 4. Category “0” was removed in the NFPA 70E 2015 Changes.

“Limited Approach” and “Restricted Approach” fields are related Shock Hazard Approach Boundaries.

These boundaries are defined in more detail in our Arc Flash Workplace Safety Guide. The “prohibited approach” boundary was removed in the 2015 NFPA 70E edition.

“Shock Risk When Cover is Removed”.

The voltage of the equipment.

Overview

The National Fire Protection Association (NFPA) details how to comply with the Occupational Safety and Health Administration's (OSHA) regulation, 29 CFR 1910.333(a), through the NFPA 70E standard.

According to the NFPA 70E standard, there are six primary responsibilities that facilities must meet. These responsibilities include:

- Training for employees

- Written safety program in place that is actionable

- Personal Protective Equipment (PPE) available for employees

Arc flash labeling is the responsibility of the employer, not the manufacturer or installer of the equipment. Labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized, creating the potential for an arc flash incident to occur.

What Equipment Requires An Arc Flash Label?

In order to comply with the label requirement of NFPA 70E, your team should understand what electrical equipment needs to be properly labeled for arc flash.

Here are a few examples of locations an arc flash label should go.

Switchboards

Ideal for un-terminated wires or cables needing superior abrasion and chemical resistance.

Panel Boards

Ideal for general marking of terminated or unterminated cables and wires that may be curved or become curved.

Industrial Control Panels

Ideal for terminated cables or wires that may need additional abrasion or chemical resistance.

Motor Control Centers

Ideal for getting larger amounts of data on small diameter wire and cables such as fiber optic cables.

Production Line

Ideal for multi-conductor cables or bundled wires/cables.

Disconnect Switches

Ideal for multi-conductor cables or bundled wires/cables.

Seven Elements of an Arc Flash Label

Now that you’re familiar with the equipment that needs labeling, here are the elements you will need to include in your arc flash label.

Danger or Warning header.

A common guideline is to use the "Danger" header when the voltage is over 600 or when the incident energy is over 40 cal/cm2. If it is less than this threshold, an orange "Warning" header is typically used.

“Incident Energy at” is the corresponding working distance.

The Institute of Electrical and Electronics Engineers (IEEE) defines this as, “the dimension between the possible arc point and the head and body of the worker positioned in place to perform the assigned task.”

“Min. Arc Rating” is the incident energy.

A measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault.

Arc Flash Boundary.

This is the shortest distance at which a person working at the time of an arc-flash may receive permanent injury (the onset of a second degree burn or worse) if not properly protected by flame-resistant (FR) clothing.

Personal Protective Equipment (PPE).

Each hazard risk category requires a different level of protection. Categories range from 1 to 4. Category “0” was removed in the NFPA 70E 2015 Changes.

“Limited Approach” and “Restricted Approach” fields are related Shock Hazard Approach Boundaries.

These boundaries are defined in more detail in our Arc Flash Workplace Safety Guide. The “prohibited approach” boundary was removed in the 2015 NFPA 70E edition.

“Shock Risk When Cover is Removed”.

The voltage of the equipment.

7 Elements of an Arc Flash Label

Now that you’re familiar with the equipment that needs labeling, here are the elements you will need to include in your arc flash labels.

-

Danger or Warning header

A common guideline is to use the "Danger" header when the voltage is over 600 or when the incident energy is over 40 cal/cm2. If it is less than this threshold, an orange "Warning" header is typically used.

-

Incident Energy at is the corresponding working distance

The Institute of Electrical and Electronics Engineers (IEEE) defines this as "the dimension between the possible arc point and the head and body of the worker positioned in place to perform the assigned task."

-

Min. Arc Rating is the incident energy

A measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault.

-

Arc Flash Boundary

This is the shortest distance at which a person working at the time of an arc-flash may receive permanent injury (the onset of a second degree burn or worse) if not properly protected by flame-resistant (FR) clothing.

-

Personal Protective Equipment (PPE)

Each hazard risk category requires a different level of protection. Categories range from 1 to 4. Category "0" was removed in the NFPA 70E 2015 Changes.

-

Limited Approach and Restricted Approach fields are related Shock Hazard Approach Boundaries."

These boundaries are defined in more detail in our Arc Flash Workplace Safety Guide. The "prohibited approach" boundary was removed in the 2015 NFPA 70E edition.

-

Shock Risk When Cover is Removed

The voltage of the equipment.

Training Requirements

Retraining should occur every 3 years, and employees must also be retrained if their job duties change, or when procedures are not being followed (as observed by annual inspections or supervision).

Training should include:

- Specific hazards associated with electrical energy

- Special precautionary techniques and safety related work practices

- PPE, insulating and shielding materials, insulated tools and test equipment

- Emergency response and AED training

- Skills and techniques to distinguish energized parts determine nominal voltages

- Approach distances

- Decision making process and ability to perform job tasks

Training sessions must be documented and verified at least annually, and participants must be able to demonstrate knowledge. To help keep your workplace safe and compliant, Brady Safety offers a custom approach to Arc Flash Training.

Easily find gaps in your arc flash safety program

Use our arc flash program checklist tool to quickly identify your needs

NFPA 70E 2024 update

The standard gets updated every three years. Here’s what’s new in 2024.

The NFPA 70E Standard for Electrical Safety in the Workplace is revised every three years by you (the public) and industry. In the 2024 edition, you’ll find proactive ways to stay safe when working with energized equipment and systems. It features:

- An increased emphasis on risk assessment and control

- More guidance on training and education requirements

- Better clarification on PPE usage in various settings

The 2024 edition also includes additions and reorganized sections. Some highlights include:

Labeling: An update was added in the 2024 edition to NFPA 70E Article 130.5(H): Equipment Labeling. In addition to labeling the arc flash boundary and voltage method of defining PPE requirements, you'll need to ensure labels are of sufficient durability for the environment involved.

Scope: Each article now has a scope, which caused some sections to be renumbered

Definitions: All are now located in Article 100

Terms: ‛Electric’ now appears before ‛shock’, and ‛Leather’ was deleted to permit other protector types

Emergency response plan: It’s now required in the job safety plan

A safe work condition: It was renumbered from 120.5 and 7 to 120.6 and they added the words "At each point of work".

Shock approach boundary tables: These are adjusted to correspond with OSHA 1910.269

Normal operation of electrical equipment: Equipment must be rated to handle available fault current.

Assessing the condition of maintenance: New section added: Informative Annex S – informational only

Here’s what’s new in 2021.

The NFPA 70E standard was updated for 2021, including adding detail to term definitions, clarifying requirements and reorganizing information for a more logical progression. The most notable changes are:

- Extra emphasis on the employer's responsibility to create an electrically safe work condition

- Stressing that doing energized work with PPE should be a last resort.

Key updates to terms

- Electrically safe work condition: Note added to clarify that an electrically safe work condition is not a procedure, but a state where all hazardous electrical conductors or circuit parts to which a worker might be exposed are de-energized.

- Fault current: Note added to clarify that available fault current varies by location in the circuit.

- Shock hazard: Updated to indicate that parts must be exposed to be a hazard.

Other notable changes to NFPA 70E for 2021

- Calls out the importance of de-energizing as a requirement of an Electrical Safety Program. Programs now must include a policy on establishing an electrically safe work condition.

- Clarifies that the lockout or tagout program must be either part of the electrical safety program, or must reference the lockout or tagout program.

- Confirms that electrical safety is based on all equipment being used as intended by the manufacturer.

- Revises requirements of a lockout device to align with OSHA 1910.333(b)(2)(iii)(E).

- Includes new or revised tables for estimating the likelihood of occurrence of an arc flash incident and guidelines around rubber insulating gloves, tools and equipment.

- Clarifies language around the use of barriers or barricades.

- Adds new information on safety-related requirements for capacitors.

Looking for more details?

Arc Flash Safety Services

Let our safety professionals guide you with assessments, audits, training and more.

Product Recommendations

Need to post arc flash labels on your electrical equipment? Here are our top recommended products to get you started.Resources

Arc Flash Workplace Safety Guide

Better Understand arc flash, risk assessments, and labeling requirements.

For a Guide Contact Us

NFPA 70E 2018 Changes

The NFPA 70E gets updated every three years. See what’s new in 2018.

Learn More